- Home

- Industrial Fans & Blowers

- Centrifugal Fans

Design and Manufacturing of Centrifugal Fans

Centrifugal Fan Basics

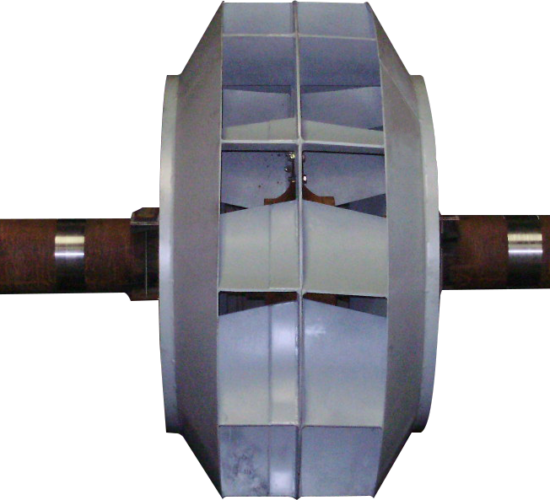

Centrifugal fans are used to move an air stream at an angle to the intake (usually 90°). A ducted housing is used to direct air in the intended direction while the fan’s blades are mounted on a circular hub around the fan wheel. The kinetic energy of the rotating blades in a centrifugal fan accelerates and increases the pressure of the air. The use of centrifugal energy to do the work gives this variety of fan its name.

The blades in a centrifugal fan can be forward-curved, backward-curved, or straight radial blades. Each type of centrifugal fan blade has its own best-use scenario that depends on system requirements such as the system pressures, volumes, and space requirements.

Axial Fan v. Centrifugal Fan

Axial fans feature blades that are radially-mounted, around an axis. The outflow of an axial fan is parallel to the inflow, as in a standard box fan. They are mostly used in situations where a large volume of air needs to be moved from one area to another. Due to the low pressure of their airflow they only need a low power input.

Centrifugal fans generate high pressure and are ideal for drying and HVAC systems. Their enclosed structure makes them useful in harsh environments and also helps with particulate reduction, which makes them an optimal choice for air pollution and filtration systems. They have many additional industrial uses due to their simple construction, high energy efficiency, and low cost.

Centrifugal Blower Design

Our practiced team’s experience during the project discovery process insures that your performance and budgetary expectations will be satisfactorily fulfilled. A concrete set of drawings will be used to drive the manufacturing, and installation of your completed centrifugal fan.

Centrifugal fans are quiet, reliable, and sturdy. Keeping cost in line, by minimizing downtime, is a key concern during fan design. Total life-cycle costs are more and more important for all plant operations.

Centrifugal Fan Manufacturing

Our manufacturing team draws from the company’s service and repair experience to insure that new centrifugal fans will operate efficiently and with a minimum amount of servicing. No matter your centrifugal fan needs our manufacturing team can design and build the cooling fan, exhaust fan, extractor fan, or other type of industrial centrifugal blower – standard or custom, our design or yours, any fan, any size.